TFS Fabrication Department

Metal Made-To-Measure

Gates & Railings

Our Gates & Railings are fully bespoke, designed and built to suit your property, your style, and your exact measurements. From the first conversation, our engineers work with you to shape the look and feel you want, then take it through design, workshop fabrication, and final installation, keeping you updated at every stage.

Design Process

Part of the process is helping you find the perfect product for your property and as expert metal fabricators we can design a piece that will meet your high specifications. If you would like automated gates Kent and South London.

Fabrication

As metal fabricators with 30 years of experience, we can construct the perfect product for you and do so quickly and efficiently. Of course, leave it to us at TFS to expertly install your metal product.

Automated

Gates

Staircases

Gates

& Railings

Handrails

Repairs & Upgrades

Whether your railings are broken or your gate system needs an upgrade, get in touch with us and we will visit your home and provide all repairs and can advise on an upgrade should you desire one.

Maintenance & Servicing

If you have an automated gate system, regular maintenance is key to ensure the long life of your fully automated gate system. We are experts in identifying issues before they mushroom into major problems.

Step By Step : Timeline

Explore the step-by-step process of our in-house fabrication team, from initial design concept through CAD development, workshop build, delivery, and final installation, with clear collaboration and updates at every stage to maintain quality and keep your timeline on track.

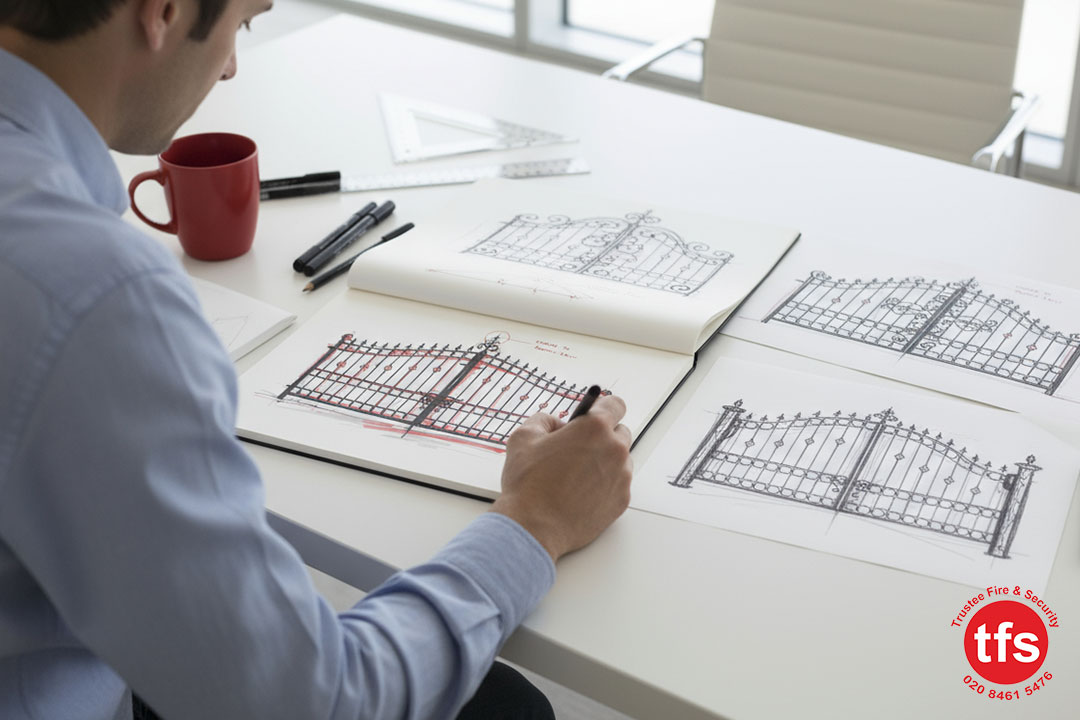

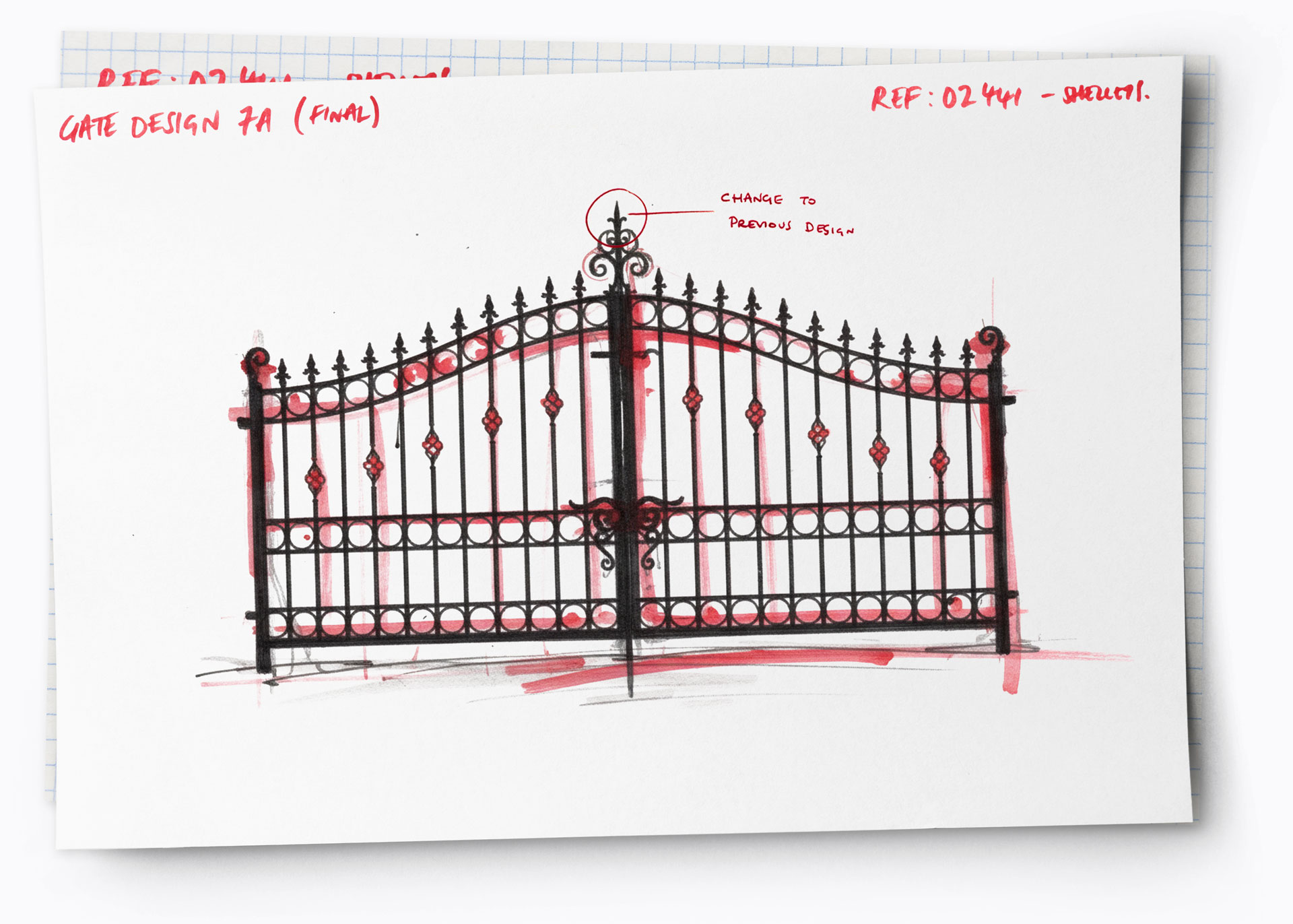

Step One :

Sketch & Design

From the outset we work with you and/or your team to agree goals and the look & feel you’re after. We turn that into a simple design brief, then prototype and refine until it fits. You can be hands-on in workshops or stick to milestone check-ins, your choice. We share clear visuals and quick updates so feedback is easy. By the end of step one you have a design that meets your requirements and feels right for your project.

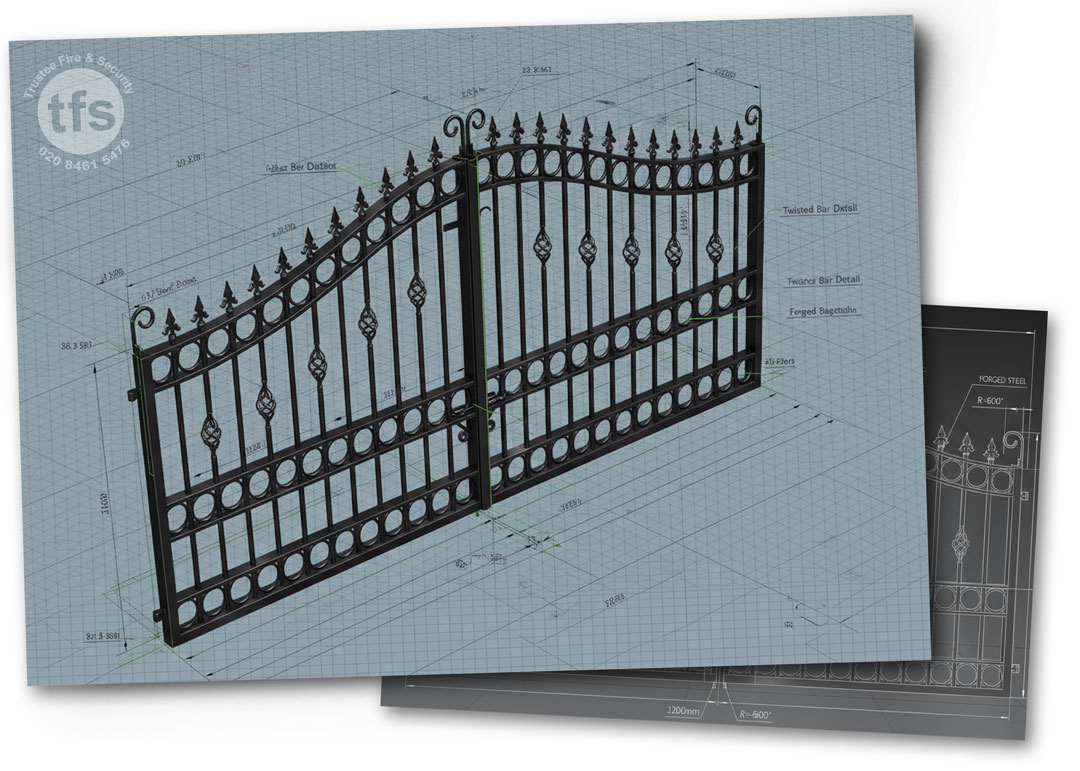

Step Two :

CAD Design

Once the concept is agreed with you and our engineer, we hand it to Chris, our in-house CAD specialist. Chris builds the 3D model, checks tolerances, materials, and fixings, and resolves clashes. He also prepares drawings, cut lists, and CAM files so the next stage runs smoothly. You receive regular updates with clear visuals and short notes, making feedback easy at each checkpoint. We aim to complete this phase quickly and carefully, locking the specification and timeline so fabrication can start on schedule.

Step Three :

Fabrication

Now the fun part. Our workshop fabrication specialists take it from here. With materials pre-ordered, lead times are covered and delays are unlikely. The team work in-house to cut, machine, and assemble components while staying ahead of schedule. We track quality at each step and keep you updated, so the fabrication phase finishes smoothly and on time.

Step Four :

Installation

With fabrication complete and approved by you and our engineer, we disassemble, protect, and load everything onto the TFS truck. Delivery is scheduled to suit your site and program. On arrival we stage components for a clean install. The team works safely and quietly to minimise disruption, coordinating with other trades as needed. Once installed we test, snag, and walk you through operation and care. After final sign-off we hand over manuals and add you to our servicing and maintenance schedule.